In chemical and pharmaceutical manufacturing, process safety is a critical concern due to the handling of hazardous, reactive, or toxic materials. Agitated Nutsche Filters (ANFs) are widely used in these industries for their ability to combine filtration, washing, and drying in a single enclosed vessel. While ANFs improve efficiency and reduce product handling, ensuring process safety requires careful design, operation, and maintenance. Understanding safety considerations is essential to prevent accidents, maintain product quality, and comply with regulatory requirements.

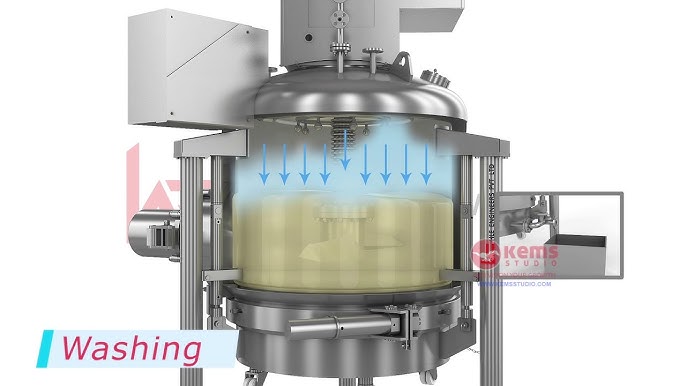

An Agitated Nutsche Filter consists of a vessel body, perforated filter plate, mechanical agitator, vacuum and heating systems, and discharge mechanisms. Its enclosed design inherently reduces exposure to hazardous chemicals and contamination risks. For industrial-grade options and detailed specifications, you can explore this Agitated Nutsche Filter, widely implemented for safe and efficient batch processing in chemical and pharmaceutical operations.

Hazard Identification

The first step in ensuring safety is identifying potential hazards associated with ANFs. Common risks include:

- Chemical Exposure: Operators may be exposed to toxic, corrosive, or reactive chemicals during loading, discharge, or cleaning if proper precautions are not taken.

- Pressure Hazards: The vessel operates under vacuum or slight positive pressure, and failure of seals, gaskets, or the vessel itself can lead to leaks or rupture.

- Thermal Hazards: Heating jackets and hot surfaces pose burn risks, especially during maintenance or cleaning operations.

- Mechanical Hazards: The agitator and moving parts can cause injury if accessed during operation.

- Dust and Particulate Hazards: Fine powders or crystalline solids can create airborne dust, which may be combustible or toxic.

Understanding these risks allows manufacturers to implement appropriate engineering controls, personal protective equipment (PPE), and procedural safeguards.

Design Considerations for Safety

Proper design is essential to ensure safe operation of ANFs. Key safety-focused design elements include:

- Sealed Vessel: The enclosed design minimizes operator exposure to hazardous materials and prevents contamination of the surrounding environment.

- Pressure Relief Systems: Vessels should be equipped with pressure relief valves or rupture discs to protect against overpressure or vacuum failure.

- Explosion-Proof Components: For handling flammable or combustible materials, agitators, motors, and electrical systems should be explosion-proof, and inert gas purging may be used to prevent ignition.

- Corrosion-Resistant Materials: Stainless steel or specialty alloys reduce the risk of leaks or failures due to chemical corrosion.

- Instrumentation and Controls: Sensors for temperature, pressure, and vacuum levels, along with automated control systems, help monitor operating conditions and provide alarms or shutdowns in case of deviations.

These design features reduce the likelihood of accidents and support compliance with regulatory standards such as OSHA, ATEX, or cGMP.

Safe Operation Practices

Even with proper design, safe operation is critical. Key operational safety measures include:

- Proper Training: Operators must be trained in the safe use of ANFs, including understanding hazards, emergency procedures, and routine maintenance requirements.

- Controlled Loading and Discharge: Ensure materials are loaded carefully to prevent spills and that discharge is conducted only when the system is depressurized and safe to access.

- Agitator Safety: Never access the vessel interior while the agitator is running. Lockout/tagout procedures should be strictly followed during maintenance.

- Temperature and Vacuum Monitoring: Continuously monitor heating and vacuum systems to prevent overheating, overpressure, or improper drying conditions.

- Use of PPE: Gloves, goggles, chemical-resistant clothing, and respiratory protection may be required depending on the material being processed.

Maintenance and Inspection

Regular maintenance and inspection are integral to process safety. Components such as seals, gaskets, agitator bearings, filter plates, and vacuum systems should be checked periodically for wear, corrosion, or damage. Proper maintenance prevents leaks, mechanical failures, and unexpected shutdowns. Cleaning procedures should be conducted according to safe handling protocols, including the use of compatible solvents, proper ventilation, and PPE.

Emergency Preparedness

Even with preventive measures, emergencies can occur. Manufacturers should develop comprehensive emergency response plans that include:

- Procedures for chemical spills or leaks.

- Contingencies for vacuum or pressure system failures.

- Steps for managing fires or explosions in case of flammable material ignition.

- Evacuation protocols and first aid procedures for exposed personnel.

Regular drills and staff training ensure readiness to handle any unexpected event safely.

Regulatory Compliance

Agitated Nutsche Filters in pharmaceutical and chemical industries must comply with various safety and quality regulations. cGMP, OSHA, ATEX, and ISO standards dictate requirements for equipment design, operation, documentation, and training. Adhering to these regulations not only ensures safety but also maintains product quality and minimizes the risk of legal and financial consequences.

Conclusion

Process safety for Agitated Nutsche Filters is achieved through a combination of robust equipment design, safe operational practices, routine maintenance, and regulatory compliance. By addressing chemical, mechanical, thermal, and pressure-related hazards, manufacturers can minimize risks and ensure safe handling of hazardous materials. Proper training, monitoring, and emergency preparedness further enhance safety while maintaining high product quality and operational efficiency. Implementing these considerations makes ANFs a reliable and safe choice for batch filtration, washing, and drying in chemical and pharmaceutical manufacturing.