Introduction

Medical connectors are critical components in modern healthcare devices, including patient monitors, imaging equipment, and therapeutic machines. These connectors provide reliable pathways for electrical signals, power, and data, making their performance vital for device functionality and patient safety. Ensuring the safety of medical connectors requires meticulous design, stringent testing, and adherence to industry standards. Manufacturers play a key role in maintaining the integrity and reliability of these components, which directly impacts healthcare outcomes.

Role of Manufacturers in Connector Safety

Medical connector safety begins with responsible and knowledgeable medical connector manufacturers. These manufacturers follow comprehensive processes to ensure that each connector meets high safety and performance standards. For healthcare providers and device developers seeking reliable, compliant solutions, medical connector manufacturers design products with precision, durability, and regulatory compliance in mind. By controlling every stage of production, from material selection to final inspection, manufacturers reduce risks such as electrical failures, signal interference, and accidental disconnections that could compromise patient care.

Material Selection and Design Considerations

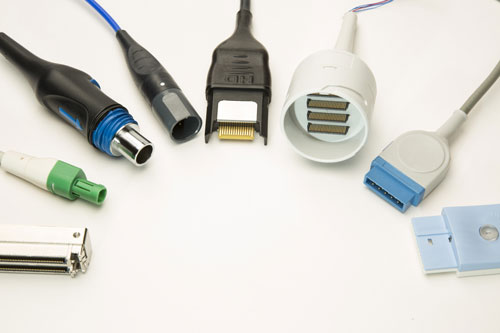

The safety of medical connectors starts with selecting the right materials. Conductive components are typically made from copper alloys and plated with gold or silver to ensure low contact resistance and resistance to corrosion. Insulating components are manufactured from high-performance plastics and polymers capable of withstanding repeated sterilization cycles, heat, and chemical exposure.

Design also plays a crucial role in safety. Connectors are engineered with secure locking mechanisms, ergonomic shapes, and color-coded interfaces to prevent misalignment or accidental disconnection. For devices that require frequent attachment and detachment, manufacturers design connectors to endure repeated mating cycles without performance degradation. These design elements enhance both reliability and user safety in clinical settings.

Rigorous Testing Procedures

Safety in medical connectors is not solely achieved through design and materials; rigorous testing is essential. Manufacturers conduct comprehensive electrical, mechanical, and environmental tests to ensure connectors perform reliably under real-world conditions. Electrical tests verify conductivity, signal integrity, and resistance to interference. Mechanical tests assess durability under repeated mating, vibration, and impact. Environmental tests evaluate resistance to moisture, temperature fluctuations, and sterilization procedures. By validating connectors through these methods, manufacturers confirm that the components meet stringent safety requirements.

Compliance with Regulatory Standards

Compliance with regulatory standards is another critical aspect of ensuring connector safety. ISO 13485, IEC 60601, and FDA guidelines provide benchmarks for quality management, electrical safety, and biocompatibility. Certified manufacturers implement strict quality control protocols to maintain compliance with these standards. This ensures that connectors are safe for use in medical devices and reduces the risk of device recalls, regulatory issues, or harm to patients.

Quality Management Systems

Medical connector manufacturers employ advanced quality management systems to maintain consistency and safety. These systems include detailed documentation of production processes, traceability of components, and continuous monitoring of product performance. Deviations from specifications are identified and corrected immediately, preventing defective connectors from reaching the market. Quality management systems also facilitate continuous improvement, ensuring that manufacturers incorporate the latest safety innovations into their products.

Innovations to Enhance Safety

Leading manufacturers are incorporating innovations that further improve connector safety. For example, some connectors now feature embedded sensors that monitor connection status and provide real-time alerts in case of faults or wear. Other designs integrate shielding to minimize electromagnetic interference, reducing the risk of data errors in sensitive diagnostic equipment. These advancements help healthcare providers rely on medical devices without concern for connector-related failures.

Impact on Patient Care

The safety measures implemented by manufacturers have a direct impact on patient care. High-quality, well-tested connectors ensure uninterrupted operation of critical devices, accurate data transmission, and reliable power delivery. This reliability reduces the risk of misdiagnosis, treatment delays, or device malfunctions in clinical settings. Safe and robust connectors also improve workflow efficiency, allowing medical staff to focus on patient care rather than device troubleshooting.

Conclusion

Ensuring safety in medical connectors requires a comprehensive approach that includes careful material selection, precise design, rigorous testing, regulatory compliance, and quality management. Medical connector manufacturers play a central role in this process, developing products that meet the highest standards of performance and reliability. Through innovation, strict protocols, and adherence to international safety standards, manufacturers provide connectors that safeguard both medical devices and patient outcomes. Investing in high-quality, safe connectors is essential for maintaining the integrity and effectiveness of modern healthcare equipment.